Product Description

Product introduction

| Gear model | Customized gear accoding to customers sample or drawing |

| Processing machine | CNC machine |

| Material | 20CrMnTi/ 20CrMnMo/ 42CrMo/ 45#steel/ 40Cr/ 20CrNi2MoA |

| Heat treattment | Carburizing and quenching/ Tempering/ Nitriding/ Carbonitriding/ Induction hardening |

| Hardness | 58-62HRC |

| Qaulity standerd | GB/ DIN/ JIS/ AGMA |

| Accuracy class | 5-8 class |

| Shipping | Sea shipping/ Air shipping/ Express |

Factory introduction

ZheJiang Yingxing Gear Co., LTD is set product development, production and sales of specialized enterprises, the company was founded in 2007, is located in Xihu (West Lake) Dis. Bridge River, 50 kilometers from the provincial capital HangZhou city, convenient transportation.

The company has modern professional production workshop covers an area of 30,000 square meters, 120 employees, including professional and technical staff of 30 people. We buy the advanced processing center equipment from Germany and American. We produce the gear for reducer,agricultural machinery, construction machinery, oil drilling rig,and other aspects of the production. The company has been appraised as ZheJiang quality products, corporate credit quality units. The company has offices in HangZhou.

Our products sell well in China and exported to Europe, the Americas, the Middle East, Southeast Asia and other countries. My company adhered to the “good faith, winning by quality, first-class service will be presented to our customers” for the purpose, we are willing to be honest with you, and work together for a better tomorrow.

Factory pictures and cerfitication

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Marine, Agricultural Machinery, Oil Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | 6 Step |

| Customization: |

Available

| Customized Request |

|---|

Can spiral gears be used in automotive applications?

Yes, spiral gears can be used in automotive applications and provide several advantages in this context. Here’s why spiral gears are suitable for automotive applications:

- Noise Reduction: Spiral gears offer significant noise reduction compared to other gear types, making them ideal for automotive applications that require quiet operation. The helical tooth arrangement minimizes gear meshing noise by providing gradual tooth engagement, reducing impact and vibration.

- Smooth Operation: The gradual tooth engagement of spiral gears also contributes to smoother gear operation. This smoothness helps to improve shifting performance, leading to enhanced driving comfort and reduced wear on transmission components.

- High Load Capacity: Spiral gears have a high load-carrying capacity, which is important in automotive applications where gears are subjected to varying loads. They can handle the torque requirements of transmissions and differential systems effectively.

- Efficient Power Transmission: Spiral gears offer efficient power transmission due to their helical tooth profile. This efficiency helps optimize fuel consumption and overall vehicle performance. By reducing energy losses through improved tooth contact and reduced sliding friction, spiral gears contribute to better power transfer.

- Durability and Reliability: Automotive applications demand gears that can withstand continuous use and provide long-term reliability. Spiral gears are known for their durability, thanks to load distribution and reduced stress concentration. They can maintain reliable performance even under challenging conditions.

- Axial Thrust Compensation: Spiral gears can be designed with opposite helix angles to cancel out axial thrust. This feature is particularly beneficial in automotive applications where minimizing axial forces is crucial. It simplifies gear design and reduces the need for additional components, enhancing space efficiency.

Considering their noise reduction capabilities, smooth operation, high load capacity, efficient power transmission, durability, and axial thrust compensation, spiral gears are well-suited for various automotive applications. They are commonly used in transmissions, differentials, and other drivetrain components to ensure reliable and efficient power transfer, contributing to overall vehicle performance and comfort.

How do you calculate the gear ratio in a spiral gear system?

The gear ratio in a spiral gear system can be calculated by comparing the number of teeth on the driving gear (pinion) to the number of teeth on the driven gear (gear). The gear ratio represents the ratio of the angular velocity (speed) of the driving gear to the angular velocity of the driven gear. Here’s the formula to calculate the gear ratio:

Gear Ratio = Number of Teeth on Driven Gear / Number of Teeth on Driving Gear

For example, consider a spiral gear system where the driving gear (pinion) has 20 teeth, and the driven gear (gear) has 40 teeth. The gear ratio can be calculated as follows:

Gear Ratio = 40 / 20 = 2

In this example, the gear ratio is 2, which means the driven gear will rotate at half the speed of the driving gear. This calculation assumes that the gears have the same module (gear size) and that there are no additional gear stages in the system.

It’s important to note that the gear ratio determines the speed and torque relationship between the driving and driven gears. A gear ratio greater than 1 (e.g., 2, 3, etc.) indicates a reduction in speed and an increase in torque, while a gear ratio less than 1 (e.g., 0.5, 0.75, etc.) indicates an increase in speed and a reduction in torque.

When working with spiral gears, it’s essential to consider the helix angle and axial thrust in addition to the gear ratio to ensure proper gear design and performance.

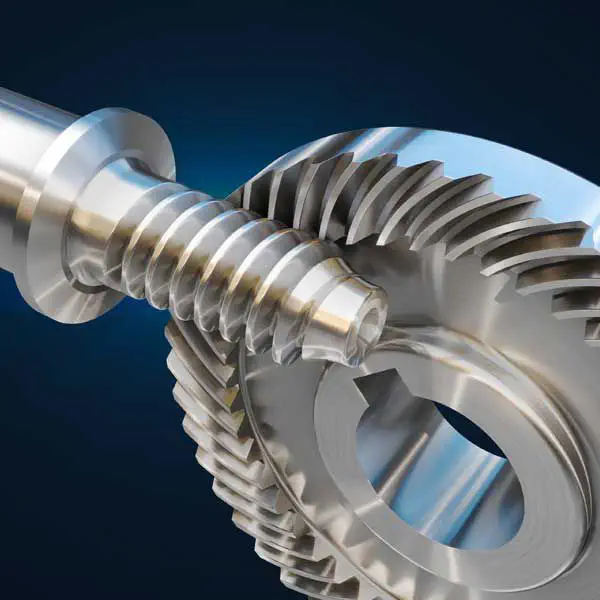

Can you describe the unique tooth profile of spiral gears?

The unique tooth profile of spiral gears, also known as helical gears, sets them apart from other gear types. Here is a description of the key characteristics of the tooth profile:

- Helical Shape: The teeth of spiral gears are helically shaped, meaning they have a curved or slanted form. This helical shape is a result of the helix angle, which is the angle between the tooth surface and the gear axis. The helical shape allows for gradual tooth engagement and smooth gear operation.

- Curved Tooth Surface: The tooth surface of spiral gears is curved or oblique due to the helical shape. This curved profile enables the teeth to engage gradually and smoothly as the gears rotate, reducing impact and noise during gear meshing.

- Lead: The lead of a spiral gear refers to the distance the gear advances axially in one complete revolution. The lead is determined by the helix angle and the number of teeth on the gear. The lead affects the contact pattern and gear meshing characteristics.

- Contact Pattern: When spiral gears mesh, the contact pattern between the teeth changes as the gears rotate. Initially, the contact starts near the smaller end of the tooth and gradually moves across the tooth face as the gears rotate. This shifting contact pattern helps distribute the load over multiple teeth and reduces localized stresses.

- Helix Angle: The helix angle is the angle between the tooth surface and the gear axis. It determines the amount of helical shape in the tooth profile. A larger helix angle results in a more pronounced helical shape, while a smaller angle produces a shallower helix. The helix angle affects the load-carrying capacity, smoothness of operation, and axial thrust characteristics of the spiral gears.

These unique characteristics of the tooth profile in spiral gears, such as the helical shape, curved tooth surface, lead, contact pattern, and helix angle, contribute to their smooth operation, efficient power transmission, and ability to handle high loads. The tooth profile design of spiral gears is crucial in achieving reliable and effective gear meshing in various mechanical systems and applications.

editor by CX 2024-04-04