Product Description

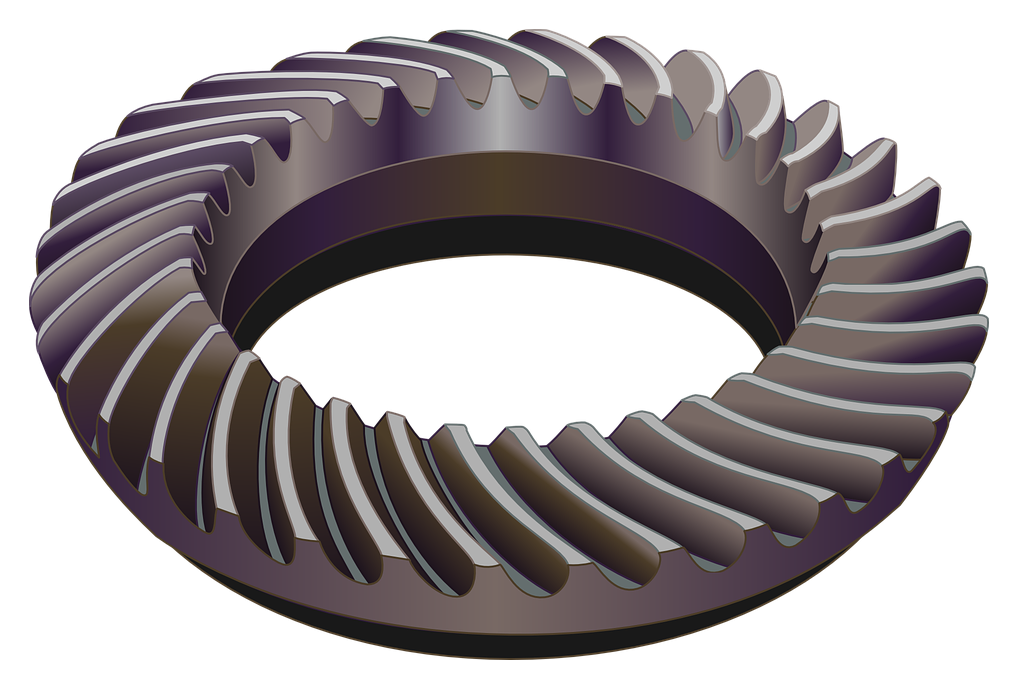

OEM Steel Hardness Helical Worm Rack Straight Spiral Spur Bevel Gears For Logistics Equipment

Transmission signal: rely on the teeth of the driving wheel to push the teeth of the driven wheel in turn to transmission the motion and power between the 2 shafts.

Features of bevel gears:

1.Mesh transmission , accurate transmission ratio, stable transmission and low noise.

2. It is applicable to a wide range of power and speed.

3.High efficiency, long life, safe and reliable work.

4. The cost is not very high and needs special equipment for processing.

Product Parameters

| Product name | Bevel Gear |

| Materials Available | Stainless Steel, Carbon Steel, Brass, Bronze, Iron, Aluminum Alloy,Copper,Plastic etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Surface Treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| BORE | Finished bore, Pilot Bore, Special request |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Pressure Angle | 20 Degree |

| Hardness | 55- 60HRC |

| Size | Customer Drawings & ISO standard |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001:2008 |

| Machining Process | Blanking, lathe, semi finishing, heat treatment, decarbonization, rough grinding, semi finishing, fine grinding, finished product inspection |

| Applications | Electric machinery, metallurgical machinery, environmental protection machinery, electronic and electrical appliances, road construction machinery, chemical machinery, food machinery, light industrial machinery, mining machinery, transportation machinery, construction machinery, building materials machinery, cement machinery, rubber machinery, water conservancy machinery and petroleum machinery |

Company Profile

Packaging & Shipping

FAQ

| Main markets | North America, South America,Eastern Europe,Weat Europe,North Europe.South Europe,Asia |

| How to order | *You send us drawing or sample |

| *We carry through project assessment | |

| *We give you our design for your confirmation | |

| *We make the sample and send it to you after you confirmed our design | |

| *You confirm the sample then place an order and pay us 30% deposit | |

| *We start producing | |

| *When the goods is done,you pay us the balance after you confirmed pictures or tracking numbers | |

| *Trade is done,thank you! |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can spiral gears be used in automotive applications?

Yes, spiral gears can be used in automotive applications and provide several advantages in this context. Here’s why spiral gears are suitable for automotive applications:

- Noise Reduction: Spiral gears offer significant noise reduction compared to other gear types, making them ideal for automotive applications that require quiet operation. The helical tooth arrangement minimizes gear meshing noise by providing gradual tooth engagement, reducing impact and vibration.

- Smooth Operation: The gradual tooth engagement of spiral gears also contributes to smoother gear operation. This smoothness helps to improve shifting performance, leading to enhanced driving comfort and reduced wear on transmission components.

- High Load Capacity: Spiral gears have a high load-carrying capacity, which is important in automotive applications where gears are subjected to varying loads. They can handle the torque requirements of transmissions and differential systems effectively.

- Efficient Power Transmission: Spiral gears offer efficient power transmission due to their helical tooth profile. This efficiency helps optimize fuel consumption and overall vehicle performance. By reducing energy losses through improved tooth contact and reduced sliding friction, spiral gears contribute to better power transfer.

- Durability and Reliability: Automotive applications demand gears that can withstand continuous use and provide long-term reliability. Spiral gears are known for their durability, thanks to load distribution and reduced stress concentration. They can maintain reliable performance even under challenging conditions.

- Axial Thrust Compensation: Spiral gears can be designed with opposite helix angles to cancel out axial thrust. This feature is particularly beneficial in automotive applications where minimizing axial forces is crucial. It simplifies gear design and reduces the need for additional components, enhancing space efficiency.

Considering their noise reduction capabilities, smooth operation, high load capacity, efficient power transmission, durability, and axial thrust compensation, spiral gears are well-suited for various automotive applications. They are commonly used in transmissions, differentials, and other drivetrain components to ensure reliable and efficient power transfer, contributing to overall vehicle performance and comfort.

How do spiral gears handle variations in speed and load conditions?

Spiral gears, also known as helical gears, are designed to effectively handle variations in speed and load conditions. Their unique tooth profile and design features allow them to adapt to changing operating conditions. Here’s how spiral gears handle variations in speed and load:

- Gradual Tooth Engagement: The helical tooth arrangement in spiral gears enables gradual tooth engagement as the gears mesh. This characteristic is advantageous when dealing with speed variations. The gradual engagement reduces impact and minimizes the shock loads that can occur during rapid changes in speed, ensuring smoother gear operation and improved reliability.

- Load Distribution: Spiral gears distribute the load across multiple teeth due to their helical tooth arrangement. This load distribution capability is beneficial when encountering variations in load conditions. By spreading the load over multiple teeth, spiral gears can handle higher loads and minimize stress concentrations on individual teeth. This feature helps prevent premature wear and tooth failure, ensuring better performance under changing load conditions.

- Efficient Power Transmission: Spiral gears offer efficient power transmission, even when there are variations in speed and load. The gradual tooth engagement, combined with the curved tooth profile, reduces sliding friction and ensures smooth gear operation. This efficiency in power transmission helps maintain consistent performance and minimizes energy losses, regardless of speed and load variations.

- Ability to Handle Shock Loads: Spiral gears have the ability to handle shock loads that may occur during sudden changes in load or speed conditions. The gradual tooth engagement and load distribution characteristics help absorb and distribute the impact forces, reducing the risk of gear damage or failure. This resilience to shock loads enhances the overall durability and reliability of spiral gears.

- Flexibility in Gear Design: Spiral gears offer flexibility in gear design, allowing for customization to meet specific speed and load requirements. The helix angle, number of teeth, and tooth profile can be tailored to optimize performance under varying operating conditions. This adaptability in gear design ensures that spiral gears can effectively handle a wide range of speed and load variations.

These features and design characteristics of spiral gears enable them to handle variations in speed and load conditions effectively. Their ability to provide gradual tooth engagement, distribute loads, transmit power efficiently, handle shock loads, and accommodate flexible gear design makes them suitable for diverse applications where speed and load variations are encountered.

How do spiral gears differ from other types of gears?

Spiral gears, also known as helical gears, have distinct differences compared to other types of gears. These differences primarily stem from the helical tooth arrangement in spiral gears. Here’s how spiral gears differ from other gear types:

- Helical Tooth Arrangement: Spiral gears have teeth that are curved in a spiral pattern, forming a helix. This is different from straight-cut gears, which have teeth parallel to the gear axis, or bevel gears, which have teeth on conical surfaces. The helical tooth arrangement in spiral gears provides various advantages such as smoother operation, increased load capacity, and improved efficiency.

- Gradual Tooth Engagement: Due to the helical tooth arrangement, spiral gears have a gradual tooth engagement as the gears rotate. This gradual contact reduces impact and noise during gear meshing, resulting in smoother and quieter operation compared to straight-cut gears.

- Axial Thrust Compensation: Spiral gears can be designed with opposite helix angles on mating gears, which helps in canceling out the axial thrust generated during gear meshing. This feature eliminates the need for additional thrust bearings and simplifies the gear design, reducing complexity.

- Load Distribution: The helical tooth arrangement in spiral gears allows the load to be distributed over multiple teeth. This enables spiral gears to handle higher torque transmission and carry heavier loads compared to straight-cut gears.

- Efficiency: Spiral gears exhibit higher efficiency due to reduced sliding friction between the teeth. The helical tooth arrangement helps minimize sliding friction, resulting in lower power losses during gear operation.

- Versatility: Spiral gears can be manufactured in various configurations, including spur, helical, and double helical designs. This versatility allows for their application in a wide range of machinery and systems, providing flexibility in gear design and usage.

These differences make spiral gears well-suited for applications that require smooth operation, high load capacity, and efficient power transmission. They are commonly used in gearboxes, automotive differentials, machine tools, and various industrial machinery.

In summary, spiral gears stand out from other gear types due to their helical tooth arrangement, resulting in smoother operation, increased load capacity, improved efficiency, and versatility.

editor by CX 2023-12-19