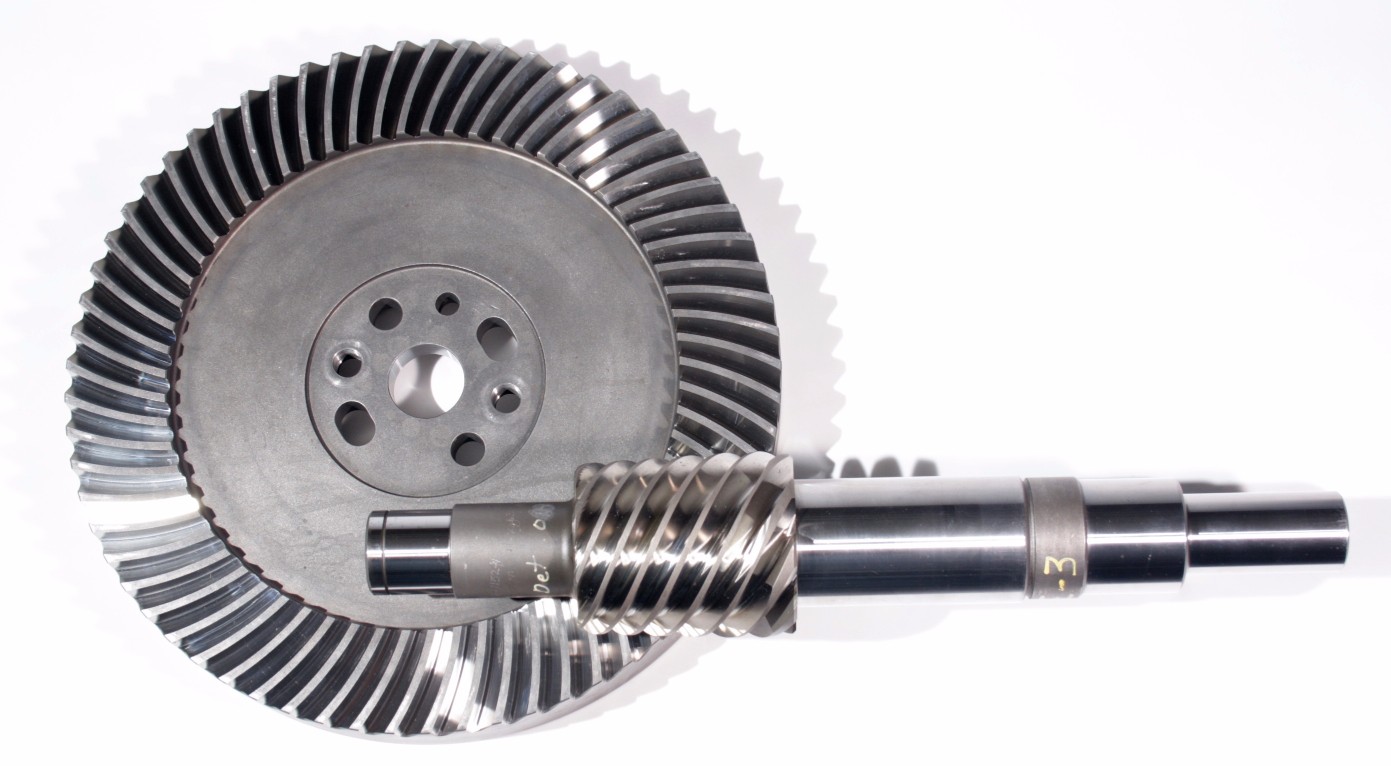

Product Description

Car steering bevel gear assy and differential failure symptoms:

The main gear assy steering bevel and differential are generally an assembly. The main function of the main steering bevel is to reduce speed, increase torque, and improve driving force. Rear-wheel drive vehicles also change the direction of power transmission through the steering bevel and bevel teeth of the main gear assy! The left function of the differential is to distribute power to the left and right wheels to ensure that the left and right wheels rotate at different speeds when the vehicle turns!

HDAG Analysis and repair methods for rear axle main steering bevel failure:

When a vehicle is driving, various emergencies often occur, such as the vehicle not moving after shifting into gear. At this time, we must first consider whether there is a problem with the half shaft. Generally, the half shaft splines are twisted. Or if it breaks, it will not mesh with the gear, and it will not move after shifting into gear. At this time, we’d better find a local repair station to replace a half shaft. However, the most important phenomenon of steering bevel gear failure is the problem of abnormal noise. Its specific manifestations are as follows:

1. The vehicle makes abnormal noise while driving.

Manifestation: The teeth of the active and passive gears are broken and broken. Treatment method: Replace the pair of active and passive gears, and replace the gear oil.

Manifestation: Improper clearance between active and passive gears. It makes a buzzing sound when running, and if the steering bevel shell is hot to touch after driving for a certain HangZhouage, it indicates that the gear clearance is too small. When starting, the bridge makes a choking sound, the sound is very small, and the sound increases when changing speed, indicating that the gear gap is too large. Solution: Adjust the gap between the active and passive teeth.

2. Abnormal noise occurs when going up or downhill.

Manifestation: The meshing marks of the active and passive gears are incorrect. Solution: If there is abnormal noise when going uphill, check the convex surface of the passive gear and adjust the mark of the passive gear. Abnormal noise when going downhill mainly depends on the mark on the concave surface of the driven gear. If the noise is not loud, try not to adjust it. Check whether the tooth side clearance is out of tolerance. If the noise is loud and the concave mark is very incorrect, rely on both ends or the top of the tooth root. The adjustment is opposite to the convex surface. .

3. Abnormal noise occurs when turning.

Manifestation: The bearings at both ends of the differential case are loose. There are messy sounds coming from the differential case, mostly caused by loose differential bearings. Solution: Adjust or replace the differential bearing.

Manifestation: Poor planetary gear meshing. The differential makes a whistling sound when turning and a buzzing sound when driving straight, indicating poor meshing of the row side teeth. Solution: Replace the planetary gear.

The above analysis is mostly based on the manifestations of the abnormal noise of the steering bevel gear assy. Its treatment method has found a better solution for the abnormal noise of your car, so that the driving safety of the car is better guaranteed.

Product description

| Item Name | Steering bevel, gear assy, steering bevel gear,steering rack,gearbox | ||||

| OEM/REF NO. | MB412549 | ||||

| Car Model | For CHINAMFG Delica L3 | 44200-0K030 | KK136-32-960B SK15232960 | 44200-0K571 44200-0K050 | 44200-26501 44200-26530 44200-26500 |

| 19321053 44250-5711 |

| After-sales Service: | Three Years |

|---|---|

| Warranty: | One Year |

| Type: | Gearbox |

| Material: | Aluminum |

| Certification: | ISO, Ts16949 |

| Automatic: | Automatic |

| Customization: |

Available

| Customized Request |

|---|

How do you install a bevel gear system?

Installing a bevel gear system involves several steps to ensure proper alignment, smooth operation, and efficient power transmission. Here’s a detailed explanation of how to install a bevel gear system:

- Preparation: Before installing the bevel gear system, gather all the necessary tools and equipment. Ensure that you have the correct bevel gears, shafts, bearings, and any additional components required for your specific application. Familiarize yourself with the system’s design, specifications, and installation instructions provided by the gear manufacturer.

- Clean and Inspect: Thoroughly clean all the components of the bevel gear system, including the gears, shafts, and bearings. Inspect them for any signs of damage, wear, or defects. Replace any damaged or worn-out parts to ensure optimal performance and longevity.

- Shaft Alignment: Proper alignment of the shafts is crucial for the bevel gear system’s performance. Ensure that the shafts are aligned accurately, both angularly and axially, as specified by the manufacturer. Misalignment can lead to premature wear, increased noise, and reduced efficiency. Use precision measurement tools, such as dial indicators, to achieve the required alignment.

- Bearing Installation: Install the bearings on the shafts according to the manufacturer’s instructions. Ensure that the bearings are securely fitted and properly lubricated. Proper bearing installation helps support the shafts, reduces friction, and ensures smooth rotation of the gears.

- Gear Meshing: Carefully position the bevel gears on the shafts, ensuring proper meshing between the teeth. The gear teeth should engage smoothly and evenly without any binding or excessive clearance. Achieving the correct gear meshing is crucial for efficient power transmission and to prevent premature wear or damage to the gears.

- Housing Assembly: Assemble the housing or casing that encloses the bevel gear system. Ensure that all housing components are aligned and securely fastened. Follow the manufacturer’s instructions for proper housing assembly, including the use of gaskets or seals to prevent lubricant leakage and contamination.

- Lubrication: Proper lubrication is essential for the smooth operation and longevity of the bevel gear system. Apply the recommended lubricant to the gears, bearings, and other moving parts according to the manufacturer’s specifications. Ensure that the lubricant used is compatible with the gear material, operating conditions, and environmental factors.

- Testing and Adjustment: After the installation is complete, perform a thorough system check. Rotate the shafts manually or using a suitable drive mechanism to ensure smooth gear operation, proper alignment, and absence of abnormal noise or vibration. Make any necessary adjustments, such as gear backlash or meshing depth, as per the manufacturer’s guidelines and based on the specific application requirements.

It’s important to note that the installation process may vary depending on the specific bevel gear system and application. Always refer to the manufacturer’s instructions and guidelines for the particular gear system you are working with to ensure proper installation and optimal performance.

In summary, installing a bevel gear system involves preparation, cleaning and inspection, shaft alignment, bearing installation, gear meshing, housing assembly, lubrication, and thorough testing and adjustment. Following proper installation procedures and adhering to manufacturer guidelines are essential to achieve efficient power transmission, smooth operation, and the desired performance from the bevel gear system.

How do you retrofit an existing mechanical system with a bevel gear?

Retrofitting an existing mechanical system with a bevel gear involves modifying the system to incorporate the bevel gear for improved functionality or performance. Here’s a detailed explanation of the retrofitting process:

- Evaluate the Existing System: Begin by thoroughly evaluating the existing mechanical system. Understand its design, components, and operational requirements. Identify the specific areas where the introduction of a bevel gear can enhance the system’s performance, efficiency, or functionality.

- Analyze Compatibility: Assess the compatibility of the existing system with the integration of a bevel gear. Consider factors such as available space, load requirements, torque transmission, and alignment feasibility. Determine if any modifications or adaptations are necessary to accommodate the bevel gear.

- Design Considerations: Based on the system evaluation and compatibility analysis, develop a design plan for incorporating the bevel gear. Determine the appropriate gear type, size, and configuration that best suits the retrofitting requirements. Consider factors such as gear ratio, torque capacity, tooth profile, and mounting options.

- Modify Components: Identify the components that need modification or replacement to integrate the bevel gear. This may involve machining new shafts or shaft extensions, modifying housing or mounting brackets, or adapting existing components to ensure proper alignment and engagement with the bevel gear.

- Ensure Proper Alignment: Proper alignment is crucial for the successful integration of the bevel gear. Ensure that the existing system components and the bevel gear are aligned accurately to maintain smooth and efficient power transmission. This may involve adjusting shaft positions, aligning bearing supports, or employing alignment fixtures during the retrofitting process.

- Lubrication and Sealing: Consider the lubrication requirements of the bevel gear system. Ensure that appropriate lubricants are selected and provisions for lubrication are incorporated into the retrofit design. Additionally, pay attention to sealing arrangements to prevent lubricant leakage or ingress of contaminants into the gear system.

- Testing and Validation: After the retrofitting process is complete, conduct thorough testing and validation of the modified mechanical system. Ensure that the bevel gear functions as intended and meets the desired performance requirements. Perform functional tests, load tests, and monitor the system for any abnormalities or issues.

- Maintenance and Documentation: Develop a maintenance plan for the retrofitted system, including periodic inspection, lubrication, and any specific maintenance tasks related to the bevel gear. Document the retrofitting process, including design modifications, component specifications, alignment procedures, and any other relevant information. This documentation will be valuable for future reference, troubleshooting, or potential further modifications.

Retrofitting an existing mechanical system with a bevel gear requires careful planning, engineering expertise, and attention to detail. It is recommended to involve experienced gear engineers or professionals with expertise in retrofitting processes to ensure a successful integration and optimal performance of the bevel gear within the system.

By retrofitting an existing mechanical system with a bevel gear, it is possible to enhance its capabilities, improve efficiency, enable new functionalities, or address specific performance issues. Proper analysis, design, and implementation are essential to achieve a successful retrofit and realize the desired benefits of incorporating a bevel gear into the system.

What are the benefits of using a bevel gear mechanism?

Using a bevel gear mechanism offers several benefits in various applications. Here’s a detailed explanation of the advantages of using a bevel gear mechanism:

- Change in Direction: Bevel gears are designed to transmit rotational motion between intersecting or non-parallel shafts. They enable a change in direction of motion, allowing the rotary power to be transmitted efficiently at different angles, such as 90 degrees or more. This capability is particularly useful in applications where space constraints or specific mechanical arrangements require a change in direction.

- Speed Reduction or Increase: Bevel gears can be used to achieve speed reduction or increase between the input and output shafts. By selecting bevel gears with different tooth counts, the rotational speed can be adjusted according to the desired output requirements. This feature is beneficial in applications where different speeds are needed for specific operations or to match the requirements of the driven equipment.

- Compact Design: Bevel gears offer a compact design that allows for efficient power transmission in applications with limited space. The intersecting shafts and compact arrangement of the gear teeth enable the transmission of torque and motion in a more confined area compared to other types of gear mechanisms.

- High Torque Transmission: Bevel gears are capable of transmitting high torque loads. The meshing of the gear teeth provides a strong and reliable connection, allowing for the efficient transfer of power even in heavy-duty applications. This makes bevel gears suitable for applications that require the transmission of substantial torque, such as in automotive differentials, industrial machinery, and mining equipment.

- Versatility: Bevel gears are versatile and can be designed to accommodate various operating conditions and requirements. They can be manufactured with different tooth profiles, such as straight-cut, spiral, or zerol, to optimize performance based on factors like noise reduction, load capacity, and efficiency. Additionally, bevel gears can be made from different materials, allowing them to withstand different environmental conditions and requirements.

- Smooth and Quiet Operation: The tooth geometry of spiral bevel gears provides smoother and quieter operation compared to straight-cut gears. The gradual engagement of the curved teeth reduces noise, vibration, and shock during gear meshing, resulting in quieter operation and improved overall system performance. This makes bevel gears suitable for applications where noise reduction is a critical consideration.

- Wide Range of Applications: Bevel gears find applications in various industries and systems where changes in direction, speed, and torque transmission are required. They are used in automotive differentials, marine propulsion systems, industrial machinery, robotics, aerospace systems, and more. The versatility and adaptability of bevel gears make them suitable for a wide range of applications across different sectors.

In summary, using a bevel gear mechanism provides benefits such as change in direction, speed adjustment, compact design, high torque transmission, versatility, smooth and quiet operation, and suitability for a wide range of applications. These advantages make bevel gears a preferred choice in numerous industries and systems that require efficient and reliable power transmission.

editor by CX 2023-11-03