Product Description

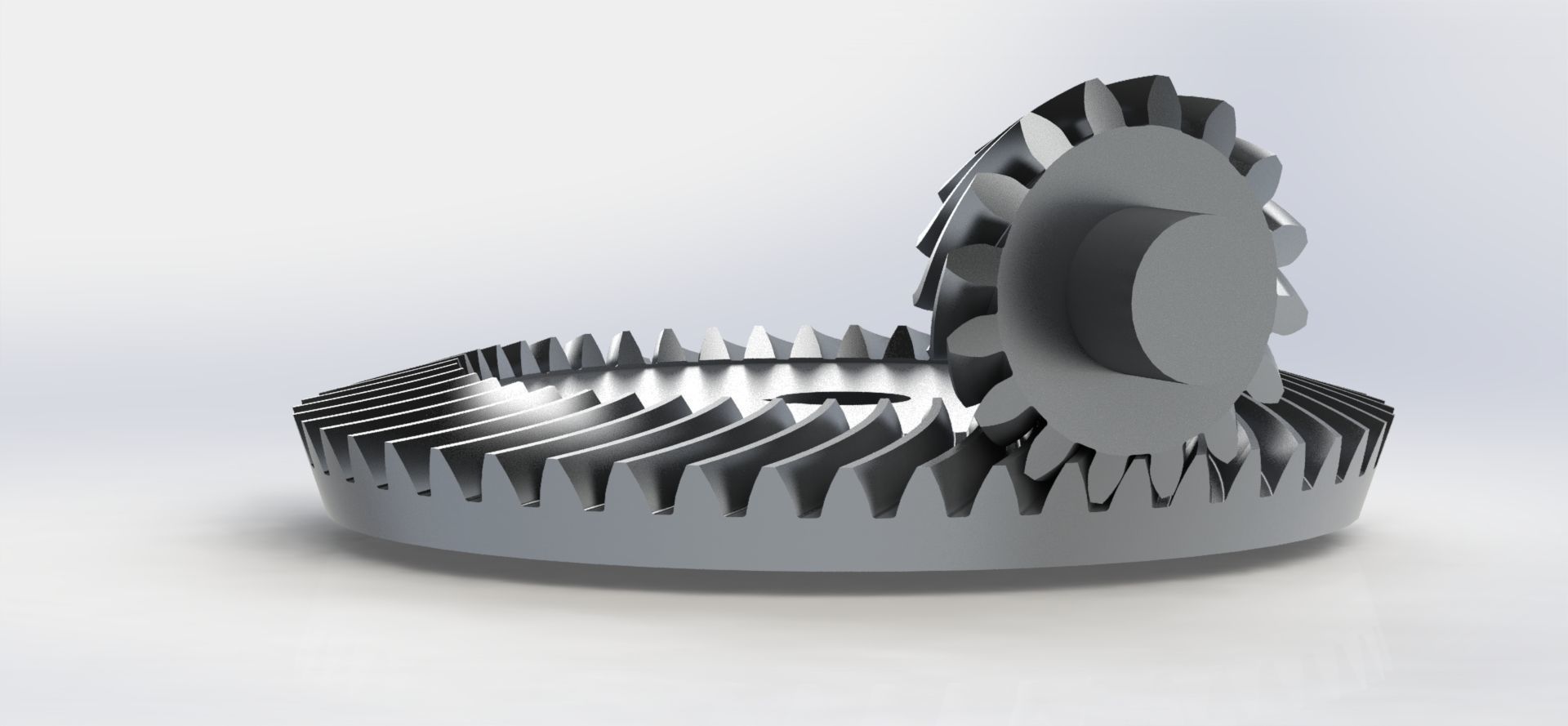

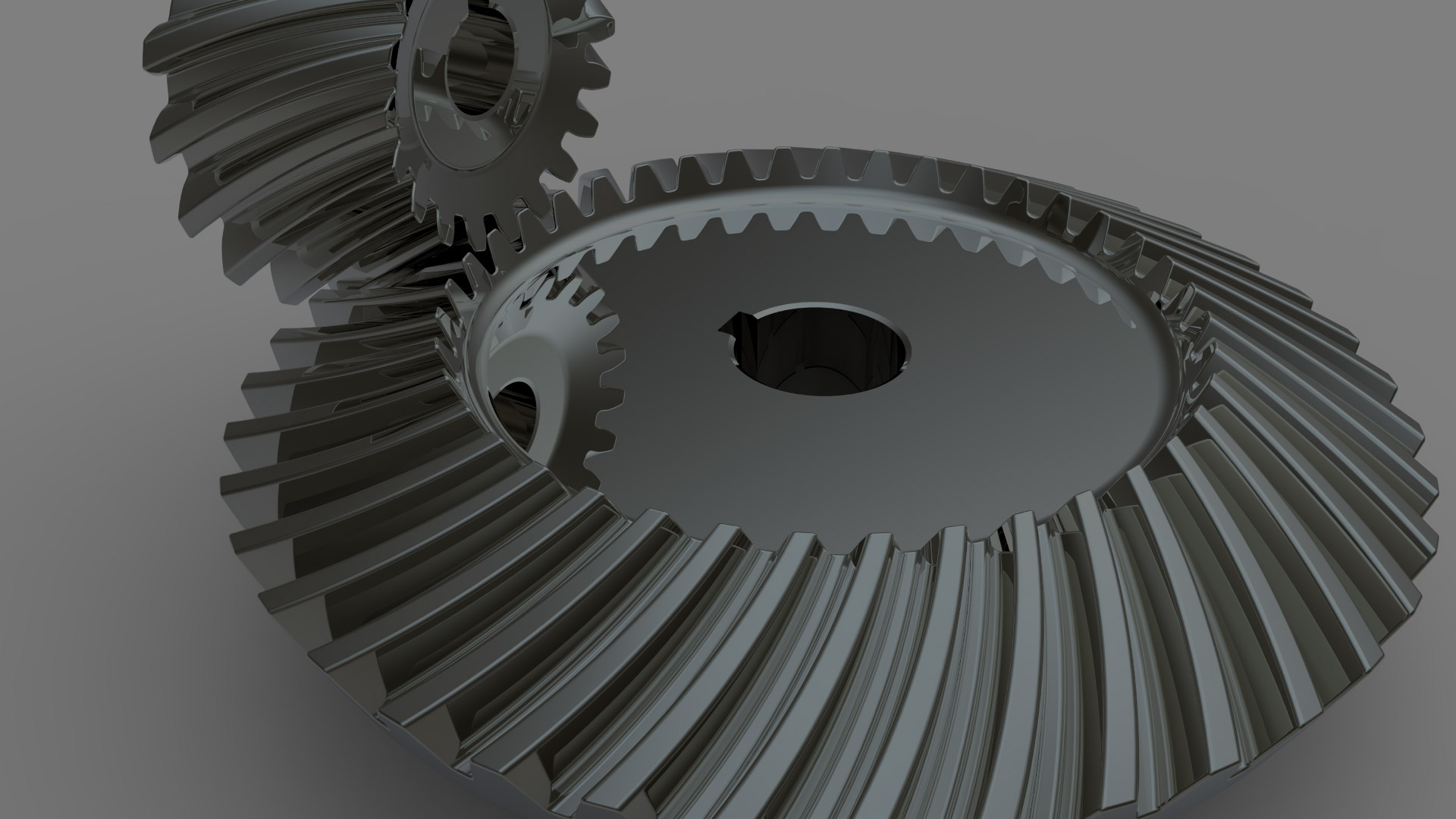

Detailed Photos

Features of S series reducer

The same model can be equipped with motors of various powers. It is easy to realize the combination and connection between various models.

The transmission efficiency is high, and the single reducer efficiency is up to 96%. three

The transmission ratio is subdivided and the range is wide. The combined model can form a large transmission ratio and low output speed.

The installation forms are various, and can be installed with any foot, B5 flange or B4 flange. The foot mounting reducer has 2 machined foot mounting planes.

Helical gear and worm gear combination, compact structure, large reduction ratio.

Installation mode: foot installation, hollow shaft installation, flange installation, torque arm installation, small flange installation.

Input mode: motor direct connection, motor belt connection or input shaft, connection flange input.

Average efficiency: reduction ratio 7.5-69.39 is 77%; 70.43-288 is 62%; The S/R combination is 57%.

S57 SF57 SA57 SAF57 S series helical worm gear box speed reducer 0.18kw 0.25kw 0.37kw 0.55kw 0.75kw 1.1kw 1.5kw 2.2kw 3kw, max. permissible torque up to 300Nm, transmission ratios from 10.78 to 196.21. Mounting mode: foot mounted, flange mounted, short flange mounted, torque arm mounted. Output shaft: CHINAMFG shaft, hollow shaft (with key, with shrink disc and with involute spline).

Product Parameters

Company Profile

Certifications

Packaging & Shipping

FAQ

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

How do spiral gears handle changes in direction and torque transmission?

Spiral gears are well-suited to handle changes in direction and torque transmission due to their unique design and characteristics. Here’s how spiral gears handle these aspects:

- Smooth Direction Changes: Spiral gears excel at transmitting power smoothly even during changes in direction. The helical tooth arrangement allows for gradual tooth engagement and disengagement as the gears rotate. This gradual engagement minimizes the impact and shock typically associated with sudden direction changes in gear systems. As a result, spiral gears provide smoother and more reliable power transmission during both forward and reverse rotations.

- Torque Transmission: Spiral gears are capable of transmitting high torque loads. The helical tooth profile and increased tooth contact area allow for efficient torque transfer between the driving and driven gears. The load distribution across multiple teeth helps to minimize stress concentration and maximize the gear’s torque-carrying capacity. This makes spiral gears suitable for applications requiring high torque transmission, such as heavy machinery and industrial equipment.

- Axial Thrust Compensation: Spiral gears can be designed with opposite helix angles on mating gears, resulting in axial thrust cancellation. This feature is particularly beneficial when dealing with bidirectional torque transmission. By canceling out the axial thrust, spiral gears can operate with reduced axial forces, ensuring smoother gear operation and minimizing the need for additional thrust bearings or complicated gear arrangements.

- Load Sharing: Spiral gears naturally distribute the load across multiple teeth due to their helical tooth arrangement. This load sharing capability helps to minimize tooth wear and fatigue, ensuring long-term durability and reliability, especially when subjected to varying torque conditions. By distributing the load, spiral gears can handle torque variations more effectively and maintain uniform tooth contact, resulting in improved performance and extended gear life.

These characteristics of spiral gears—smooth direction changes, efficient torque transmission, axial thrust compensation, and load sharing—make them highly suitable for applications that require reliable and precise power transmission in both directions. Spiral gears are commonly used in various industries, including automotive, aerospace, and heavy machinery, where the ability to handle changes in direction and torque is crucial.

Can spiral gears be used in precision machinery and equipment?

Yes, spiral gears can be used in precision machinery and equipment with excellent results. They offer several advantages that make them well-suited for such applications. Here’s why spiral gears are suitable for precision machinery and equipment:

- Smooth Operation: Spiral gears provide smooth and precise gear operation. The helical tooth arrangement ensures gradual tooth engagement, resulting in reduced impact, vibration, and noise. This smooth operation is crucial in precision machinery where precise movements and low noise levels are required.

- High Load Capacity: Spiral gears have a high load-carrying capacity, allowing them to handle heavy loads encountered in precision machinery. The helical tooth profile distributes the load across multiple teeth, reducing stress concentration. This feature enables spiral gears to transmit torque efficiently and withstand the forces associated with precision applications.

- Efficient Power Transmission: Spiral gears offer efficient power transmission, minimizing energy losses and optimizing overall system efficiency. The helical tooth profile reduces sliding friction, resulting in improved power transmission efficiency. This efficiency is particularly important in precision machinery where energy conservation and high performance are critical.

- Reduced Noise and Vibration: Spiral gears exhibit reduced noise and vibration due to their gradual tooth engagement and improved contact pattern. This feature is highly desirable in precision machinery, where noise reduction is essential for maintaining a quiet working environment and ensuring accurate operation.

- Axial Thrust Compensation: Spiral gears can be designed with opposite helix angles on mating gears to cancel out axial thrust. This axial thrust compensation simplifies gear design and reduces the need for additional components such as thrust bearings. It is particularly advantageous in precision machinery, where precise axial movement and minimal axial forces are desired.

- Reliability and Durability: Spiral gears are known for their reliability and durability. The gradual tooth engagement, load distribution, and reduced friction contribute to their long-term performance under demanding conditions. Precision machinery requires gears that can withstand continuous use and maintain high precision over time, making spiral gears a suitable choice.

Considering their smooth operation, high load capacity, efficient power transmission, noise reduction, axial thrust compensation, reliability, and durability, spiral gears are well-suited for precision machinery and equipment. They can contribute to the overall performance, accuracy, and longevity of precision systems.

What industries commonly use spiral gears in their applications?

Spiral gears, also known as helical gears, find applications in various industries due to their unique design and advantages. Here are some industries that commonly use spiral gears:

- Automotive: Spiral gears are widely used in the automotive industry, particularly in applications such as gearboxes and automotive differentials. They provide efficient power transmission, smooth operation, and the ability to handle high torque loads.

- Industrial Machinery: Many industrial machinery applications benefit from the use of spiral gears. These include heavy-duty machinery such as mining equipment, construction machinery, and manufacturing machinery. Spiral gears provide high load capacity, efficient power transmission, and reduced noise levels.

- Power Generation: Spiral gears are utilized in power generation systems such as wind turbines, hydroelectric turbines, and steam turbines. They play a critical role in transmitting power from the turbine to the generator, providing efficient and reliable power transmission in these energy production systems.

- Aerospace and Defense: The aerospace and defense industries employ spiral gears in various applications, including aircraft engines, missile systems, and satellite mechanisms. Spiral gears offer high load capacity, efficient power transmission, and the ability to withstand demanding operating conditions.

- Machine Tools: Spiral gears are commonly used in machine tools, such as milling machines, lathes, and grinding machines. These gears contribute to the smooth and precise motion of the tools, ensuring accurate machining operations.

- Robotics and Automation: Spiral gears are utilized in robotics and automation systems for their ability to provide precise and efficient motion transmission. They are crucial components in robotic arms, automated assembly lines, and other industrial automation applications.

These are just a few examples of industries that commonly use spiral gears. However, spiral gears can be found in various other applications where the advantages of smooth operation, high load capacity, efficient power transmission, and reduced noise levels are desired.

editor by CX 2024-01-08