Product Description

HangZhou CHINAMFG Industrial And Trade Co.,Ltd , located in the beautiful seaside city HangZhou China , We do professional manufacture Injection Mould , Plastic injection part, Die casting Process . Any style needed welcome asking us for quotation!!!!

Product Description

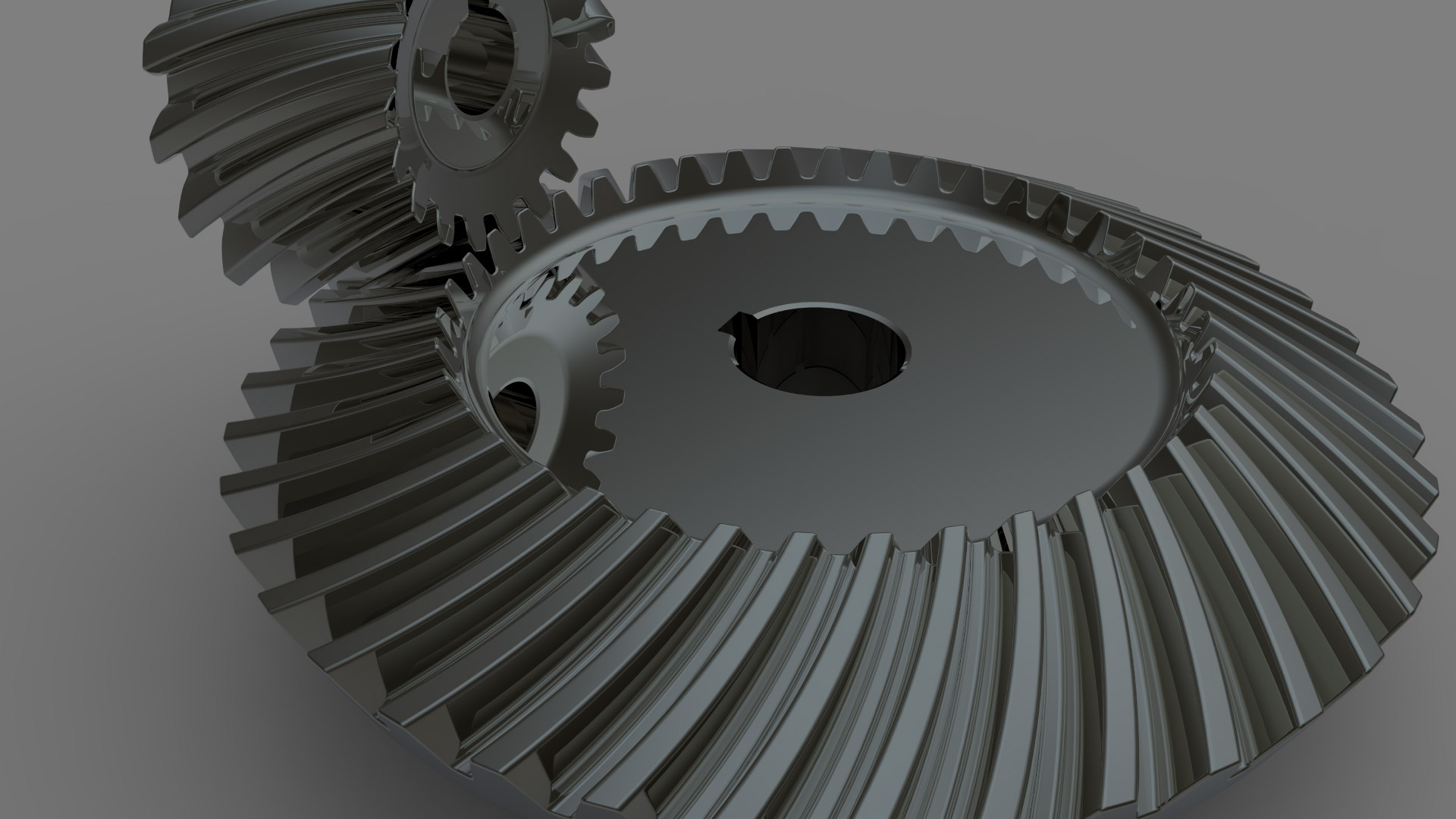

China Factory Great Precision Plastic Gear Rack and Pinion Plastic Round Audio Spiral Helical Bevel Worm Agricultural Machinery Gears Units

| Product Name | Plastic parts | |

| Material | ABS, PC, PP, PS, POM, PMMA,PBT,PVC,PA6,PA66,PA66+30%GF, PTFE,PC+ABS,TPE,etc |

|

| Surface Finish | Color painting,Texture,Silk-printing,Vacuum coating,rubber coating, etc. | |

| Cavity Variety: | One-stop solution,Multi-cavity mold,Family plastic mold,Hot runner plastic mold | |

| Quality Control | ISO/TS16949:2002 and ISO14001:2004 system | |

| Business Scope | Mold and parts designing and making,Parts machining,Injection molding, CNC prototype manufacturing |

|

| Mold Processing | CNC EDM machine processing then assembly and trial | |

| Color | Red, blue, green, yellow,all pantone colors and RAL colors |

Product Show

Factory workshop

Packing

FAQ

1. Are you manufacture factory ?

Yes ,we are in HangZhou China ,welcome to visit our factory

2.Could I get free sample ?

If we have in stock ,free sample will be available, new developing part need charge mold or tool fee then samples for free .

3.What is your Leading time

Mould 8-15 days , for production depend on the products normally 15-30days .

4.What is your payment term

Tooling or Mold 100% deposit

For Bulk order : 30% deposit, 70% before shipping

7-Days 24 Hour , any style needed welcome asking us for quotation .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the role of spiral bevel gears in drivetrain systems?

Spiral bevel gears play a crucial role in drivetrain systems, contributing to power transmission, torque redirection, and overall performance. Here’s an overview of the role of spiral bevel gears in drivetrain systems:

- Torque Transfer: Spiral bevel gears are responsible for transmitting torque between the engine and the drivetrain components. They are commonly used in vehicle differentials and transfer cases to distribute torque to the wheels or other output shafts. Their precise tooth meshing ensures efficient power transfer, allowing the vehicle to move and effectively utilize engine power.

- Torque Redirection: In drivetrain systems, spiral bevel gears are utilized to redirect torque and change the direction of power flow. For example, in rear-wheel drive vehicles, the spiral bevel gears in the differential redirect torque from the driveshaft to the rear wheels, enabling the vehicle to turn smoothly. Similarly, in four-wheel drive or all-wheel drive systems, spiral bevel gears in the transfer case redirect torque between the front and rear axles, providing traction and improved handling on various terrains.

- Gear Ratio Selection: Spiral bevel gears can be designed with different gear ratios to optimize vehicle performance. By choosing appropriate gear ratios, drivetrain systems can provide the desired balance between torque, speed, and efficiency. Spiral bevel gears allow for a wide range of gear ratio options, enabling manufacturers to tailor the drivetrain system to specific vehicle types and applications.

- Noise and Vibration Control: Spiral bevel gears are designed to minimize noise and vibrations in drivetrain systems. The helical tooth profile of spiral bevel gears allows for smoother tooth engagement, reducing gear meshing noise and vibration levels. This enhances driving comfort and reduces wear and tear on the drivetrain components.

- Compact Design: Spiral bevel gears offer a compact and space-efficient design, making them suitable for integration into drivetrain systems with limited space. Their compactness allows for efficient power transfer while optimizing the packaging of the drivetrain components within the vehicle chassis.

- Durability and Reliability: Drivetrain systems are subjected to demanding operating conditions, and spiral bevel gears are designed to withstand these challenges. They are engineered to provide durability and reliable performance under high loads, ensuring the drivetrain system’s longevity and minimizing the need for frequent maintenance.

Overall, spiral bevel gears play a vital role in drivetrain systems by enabling torque transfer, torque redirection, gear ratio selection, noise control, compact design, and ensuring durability. Their precise and efficient operation contributes to the performance, efficiency, and reliability of various vehicles, ranging from passenger cars to heavy-duty trucks and off-road vehicles.

What are the limitations of using spiral gears in certain applications?

While spiral gears offer numerous advantages, they also have certain limitations that need to be considered when selecting them for specific applications. Here are some limitations of using spiral gears:

- Axial Thrust: Spiral gears generate axial thrust due to their helical tooth arrangement. This axial thrust can impose additional forces on the gear shafts and bearings, requiring proper design considerations and potential incorporation of thrust bearings in certain applications. Managing and compensating for axial thrust is crucial to ensure smooth gear operation.

- Manufacturing Complexity: The manufacturing process for spiral gears involves more complexity compared to straight-toothed gears. The helical tooth profile requires specialized cutting tools and machining techniques, adding to the manufacturing cost and complexity. This complexity may limit their use in applications with strict cost constraints or where simplicity of manufacturing is a priority.

- Axial Space Requirement: Spiral gears require more axial space compared to parallel-axis gears. The helical tooth profile results in a longer gear face width, which can limit their use in applications with space constraints. It is important to ensure that sufficient axial space is available to accommodate the larger size of spiral gears.

- Gear Alignment: Proper gear alignment is critical for spiral gears to function optimally. Any misalignment between the driving and driven gears can result in increased noise, vibration, and premature wear. Achieving and maintaining precise gear alignment may require additional attention and care during installation and regular maintenance.

- Speed Limitations: Spiral gears may have certain speed limitations due to the potential for tooth deflection and increased heat generation. At high speeds, the centrifugal forces acting on the helical teeth can cause deflection, leading to reduced gear accuracy and increased noise. Additionally, the sliding contact between the teeth can result in higher heat generation, requiring appropriate lubrication and cooling measures in high-speed applications.

While these limitations exist, they can often be managed or mitigated through proper design, engineering, and maintenance practices. It is important to carefully evaluate the specific requirements and constraints of the application to determine whether spiral gears are suitable or if alternative gear types may be more appropriate.

What industries commonly use spiral gears in their applications?

Spiral gears, also known as helical gears, find applications in various industries due to their unique design and advantages. Here are some industries that commonly use spiral gears:

- Automotive: Spiral gears are widely used in the automotive industry, particularly in applications such as gearboxes and automotive differentials. They provide efficient power transmission, smooth operation, and the ability to handle high torque loads.

- Industrial Machinery: Many industrial machinery applications benefit from the use of spiral gears. These include heavy-duty machinery such as mining equipment, construction machinery, and manufacturing machinery. Spiral gears provide high load capacity, efficient power transmission, and reduced noise levels.

- Power Generation: Spiral gears are utilized in power generation systems such as wind turbines, hydroelectric turbines, and steam turbines. They play a critical role in transmitting power from the turbine to the generator, providing efficient and reliable power transmission in these energy production systems.

- Aerospace and Defense: The aerospace and defense industries employ spiral gears in various applications, including aircraft engines, missile systems, and satellite mechanisms. Spiral gears offer high load capacity, efficient power transmission, and the ability to withstand demanding operating conditions.

- Machine Tools: Spiral gears are commonly used in machine tools, such as milling machines, lathes, and grinding machines. These gears contribute to the smooth and precise motion of the tools, ensuring accurate machining operations.

- Robotics and Automation: Spiral gears are utilized in robotics and automation systems for their ability to provide precise and efficient motion transmission. They are crucial components in robotic arms, automated assembly lines, and other industrial automation applications.

These are just a few examples of industries that commonly use spiral gears. However, spiral gears can be found in various other applications where the advantages of smooth operation, high load capacity, efficient power transmission, and reduced noise levels are desired.

editor by CX 2024-04-11